Please show me a dyno sheet from a 3.4 with a 2.5" exhaust vs. a 2.25" exhaust to back up your theory.

Here's a good article on exhaust:

http://magnaflow.com/05news/magazine/05sportc.asp

In this article, this is what they have as pipe diameter guidelines for N/A engines:

1,500cc-2,000cc engines : 2-inch

2,100cc-2,500cc engines : 2.25-inch

2,600cc-3,000cc engines : 2.5-inch

Being that the 3400 V6 is roughly 3400cc, the previous statement that I made saying "For a big V6 like the 3400, at least 2.5" is the way to go" would be correct.

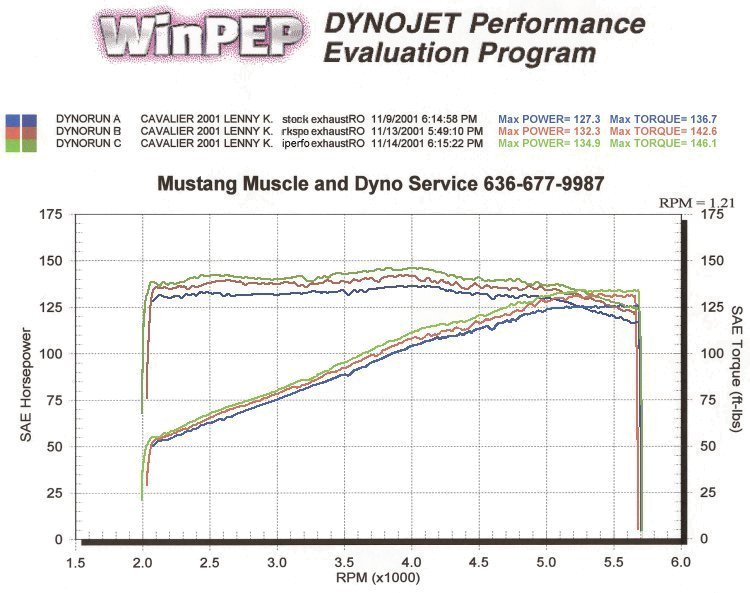

Now I'll show you a dyno sheet. This is a 2.4L Cavalier (same 2.4 engine Aleros have with same size stock exhaust and very similar routing) with stock 2" vs. 2.25" vs. 2.5" exhaust. 1000cc's smaller and 2 cylinders less than the 3400 V6 and yet the 2.5" still makes more power and maintains low end torque over the 2.25" setup:

And this is just with a cat-back setup. You'd see greater gains if the whole exhaust was replaced including the downpipe and a high flow cat, as well as greater gains still from adding a header (or headers for the V6).

Here's the website this information came from just in case you're wondering:

http://www.iperformance.biz/dyno/exhaust01.html

And since you mentioned turbos, the reason for having the biggest exhaust possible on a turbo engine is not because of forced exhaust, it's because you want all the backpressure possible off the turbine so it can spool sooner and stay spooled longer.